Innovations in Electric Vehicle Battery Technology

The landscape of electric vehicles (EVs) is continuously evolving, largely driven by significant advancements in battery technology. These innovations are crucial for enhancing vehicle range, reducing charging times, and improving overall performance, making EVs more accessible and appealing to a broader audience. Understanding the ongoing developments in battery chemistry and design is key to appreciating the future direction of sustainable personal transport and mobility solutions.

Innovations in electric vehicle (EV) battery technology are a cornerstone of the automotive industry’s shift towards sustainable transport. These advancements are not merely incremental; they represent fundamental changes in how energy is stored and delivered, directly influencing the capabilities and widespread adoption of electric and even hybrid vehicles on the road. The ongoing research and development efforts are focused on improving energy density, charging speed, lifespan, and safety, while also addressing manufacturing costs and environmental impact.

Advancements in Battery Chemistry and Performance

The core of any electric vehicle lies in its battery, and recent breakthroughs in chemistry are significantly boosting performance. Lithium-ion batteries remain dominant, but new variations are emerging, such as solid-state batteries and lithium-sulfur batteries. Solid-state batteries, for example, replace the liquid electrolyte with a solid one, potentially offering higher energy density, faster charging, and enhanced safety by reducing the risk of thermal runaway. These developments promise longer driving ranges and more robust energy storage systems. The pursuit of higher energy density means that vehicles can travel further on a single charge, addressing a primary concern for many potential EV owners.

Impact on Vehicle Design and Driving Experience

Improvements in battery technology have a profound effect on vehicle design and the overall driving experience. Smaller, lighter, and more energy-dense battery packs allow engineers greater flexibility in chassis design, contributing to better weight distribution and potentially improved aerodynamics. This can lead to enhanced handling and performance, making the electric driving experience more dynamic. The integration of advanced battery management systems also optimizes power delivery to the electric engine, improving efficiency and responsiveness. Furthermore, the modularity of newer battery designs can simplify the manufacturing process and allow for easier scaling across different vehicle types, from compact cars to larger transport vehicles.

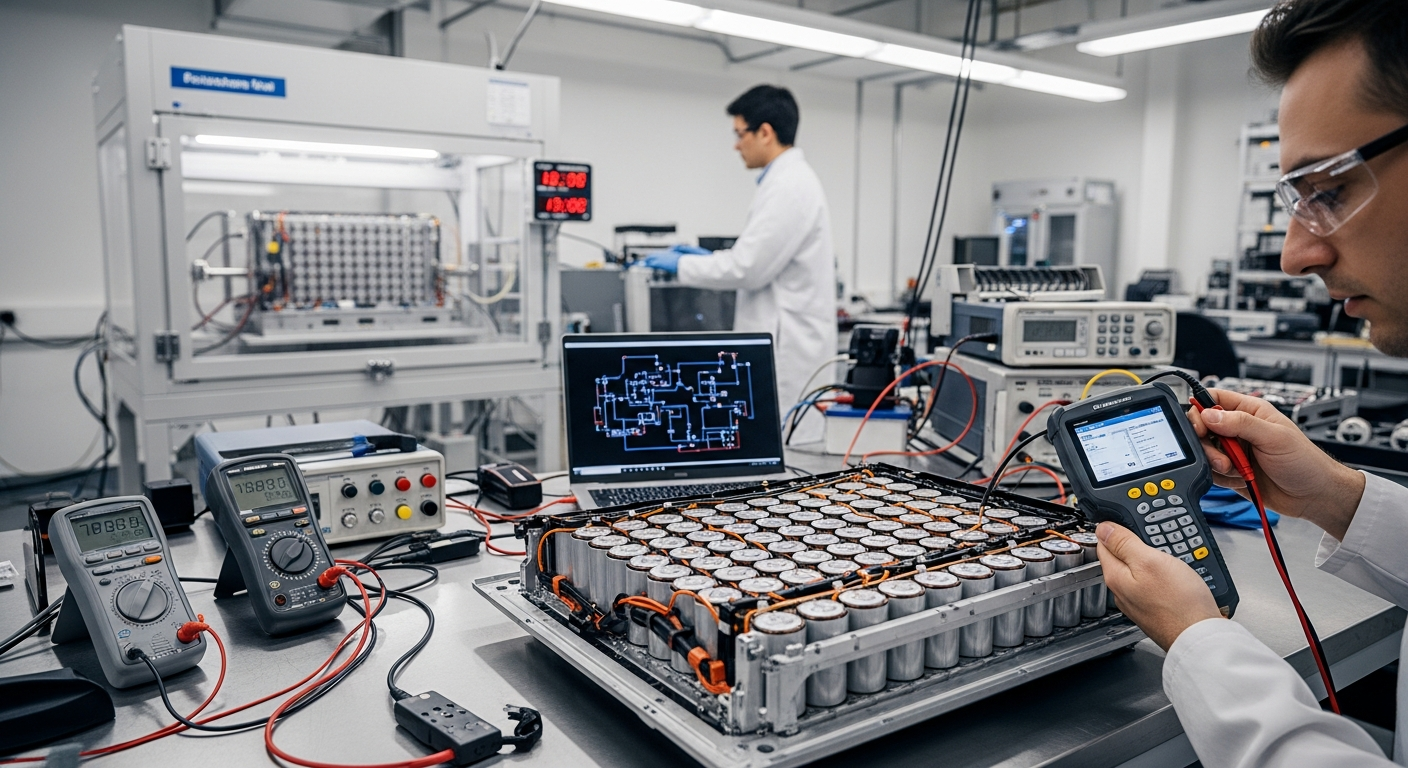

Enhancing Safety and Longevity of EV Batteries

Safety is a paramount concern in battery development. Innovations focus on preventing thermal runaway, improving crashworthiness, and ensuring long-term reliability. Advanced cooling systems and improved battery management software are vital in monitoring cell health and maintaining optimal operating temperatures, which directly contributes to the battery’s longevity and consistent performance. The goal is to create batteries that not only last for the entire lifespan of the vehicle but also maintain a high percentage of their original capacity over many years of use and charging cycles, reducing maintenance needs for owners.

Manufacturing Processes and Future Mobility

The manufacturing of EV batteries is also undergoing significant transformation, driven by the need for efficiency, cost reduction, and sustainability. New techniques are being explored for more environmentally friendly material sourcing and recycling processes, aiming to create a circular economy for battery components. Automation in battery production facilities is increasing, leading to higher precision and reduced labor costs, which ultimately makes electric vehicles more affordable. These manufacturing innovations are critical for scaling up production to meet global demand and supporting the broader shift towards electric mobility and sustainable transport solutions on the road.

Cost Considerations for Electric Vehicle Batteries

The cost of electric vehicle batteries has seen a significant decline over the past decade, making EVs more competitive with traditional internal combustion engine vehicles. While the initial purchase price of an EV can still be higher, the long-term operational costs, including ‘fuel’ (electricity) and maintenance, are often lower. Battery costs are influenced by raw material prices, manufacturing efficiency, and the scale of production. For instance, a 60 kWh battery pack, common in many mainstream EVs, might represent a substantial portion of the vehicle’s total manufacturing cost. However, as technology advances and production volumes increase, these costs are projected to continue their downward trend. The development of new chemistries also aims to reduce reliance on expensive or rare materials, further contributing to cost efficiency.

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

In conclusion, the rapid pace of innovation in electric vehicle battery technology is a key enabler for the future of sustainable transport. From advanced chemistries that enhance performance and driving range to improved safety features and more efficient manufacturing processes, these developments are making electric vehicles increasingly viable and attractive. As research continues and new materials emerge, the capabilities of EV batteries will undoubtedly continue to expand, further accelerating the transition towards a more electrified and environmentally conscious automotive landscape.